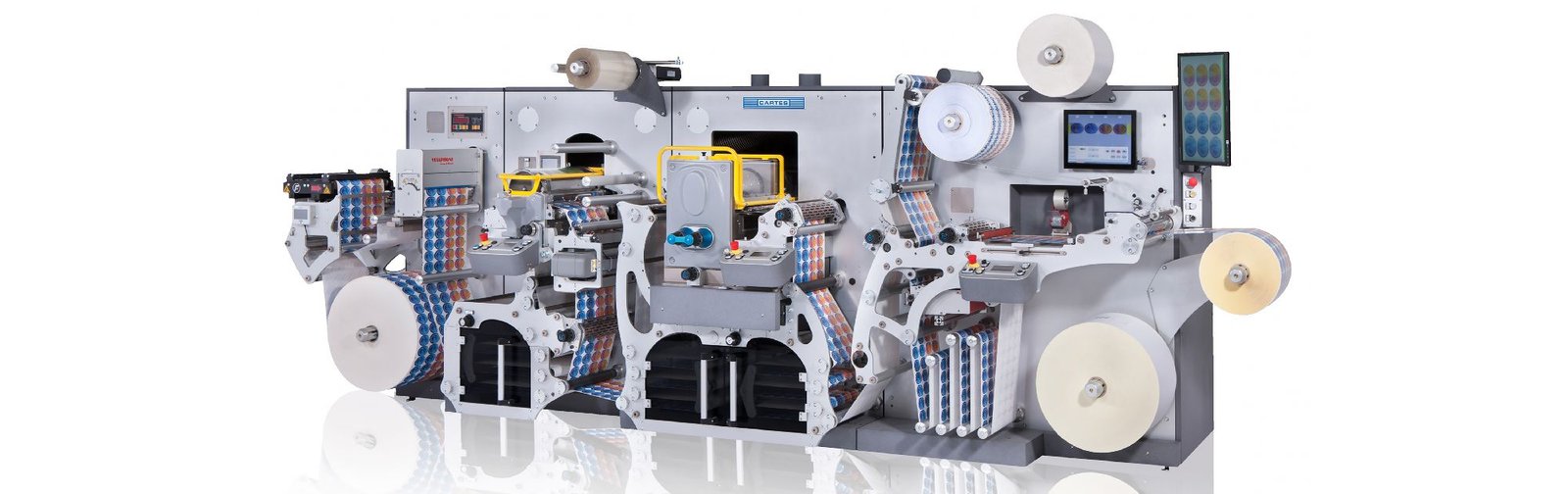

Gemini E-Line

Máquina modular de acabados para converting, ancho de banda 360 mm

La serie GEMINI

es configurable con: Impresión y barnizado flexográfico – Troquelado semi-rotativo (patentado por CARTES) – Troquelado y converting láser. También disponibiles el sistema para laminación protectiva, aplicación de cold foil, ILC®, procesar IMLy otros.

Módulos

Entrada de material

Control del material totalmente servoasistido con eje a expansión pneumática de ø76 mm para bobinas de hasta ø800 mm o 200 Kg.

Control automático del diámetro de la bobina con sensor de parada al finalizar el material, guiador electrónico con sensor por ultrasonido, superficie de empalme y dispensador de cinta.

Fotocélula de lectura para detectar marcas o contrastes de color en materiales pre-impresos.

Barnizado Flexo

a fondo lleno y reserva

La unidad de barnizado flexo está disponible en 3 versiones, todas con sistema de curado UV y tintero cerrado TRESU:

Rotativa para sólo fondos llenos,

Rotativa tanto para fondos llenos como a reserva,

a través del cambio de diferentes desarrollos

Semi-rotativa para fondos llenos y a reserva.

Control del material totalmente servoasistido con eje a expansión pneumática de ø76 mm para bobinas de hasta ø800 mm o 200 Kg.

Control automático del diámetro de la bobina con

sensor de parada al finalizar el material, guía de banda electrónico con sensor por ultrasonido, superficie de empalme y dispensador de cinta.

Fotocélula de lectura para detectar marcas o contrastes de color en materiales pre-impresos.

Troquelado por láser

La unidad de troquelado por LASER es la única existente en el mercado con fuente Semisellada® de duración ilimitada que garantiza potencia y calidad de corte constante en el tiempo, minimizando los costes de gestión y mantenimiento.

Gracias al sistema de control de la potencia del LASER por Radio Frecuencia, la máquina puede lograr el máximo rendimiento, ya que es posible procesar en un sólo ciclo: el troquelado de cualquier tipo de forma, perforación, micro-perforación, grabado, corte, medio corte así como numeración progresiva y regresiva, todos ellos programables digitalmente para lograr, en tiempo real, productos de alto valor.

Además del nuevo software de gestión de los archivos de corte, hemos desarrollado un sistema de lectura a través de códigos de barras preimpresos que permite automatizar el flujo de trabajo, haciendo posible el cambio de troqueles de forma automática.

Mediante el sistema ILC® – Invisible Laser Cutting System , es posible troquelar etiquetas con fondos de colores oscuros, evitando el característico “ borde blanco”, así como el desborde del adhesivo fuera de la etiqueta, garantizando la fluidez del proceso de aplicación.

Adicionalmente, hace posible procesar etiquetas sin soporte, como lo son las In-Mould Label.

Troquel semi-rotativo

La unidad de troquelado semi-rotativo, totalmente servo asistida, ha sido diseñada para facilitar el trabajo del operador, de manera que basten pocos segundos para instalar y ajustar un troquel.

Sus cualidades “únicas” son claves a la hora de ahorrar tiempo y desperdicio del material.

Air Gap System (AGS)

Este exclusivo sistema de ajuste, asegura un perfecto posicionamiento del cilindro magnético respecto al de contraste con una precisión milésima, de manera que se controla la incidencia del corte para evitar que el soporte sea marcado.

Se colocan los valores de espesor del troquel y del soporte del material autoadhesivo, para que el software conozca con precisión cual es la posición de ambos cilindros y así dar un punto de referencia al operador para ajustarlos a la perfección.

Image Distortion System (IDS)

Este software de gestión permite adaptar en forma automática el desarrollo troqueles elaborados para cilindros de desarrollos diferentes, con tan solo escribirlo en el panel táctil de la unidad.

Además permite restringir y aumentar la longitud de cada desarrollo de troquel hasta un 20% de la dimensión original y hasta un máximo de 5 etiquetas simultáneamente, sin que esto modifique la distancia original del espacio entre etiquetas.

Salida de material

Rebobinado integrado con sistema de corte longitudinal y desmallado.

Sistema de rebobinado totalmente servo asistido con control de tensión automático en todos los con ejes de expansión neumática ø76mm, habilitados para rotar en sentido horario y anti-horario.

Corte longitudinal estándar con 10 cuchillas oscilatorias del tipo hojillas y sistema de corte con 5 unidades de cuchillas del tipo tijera, opcional. Computador para conexión remota entre la máquina y CARTES, necesario para eventuales diagnósticos y actualizaciones.